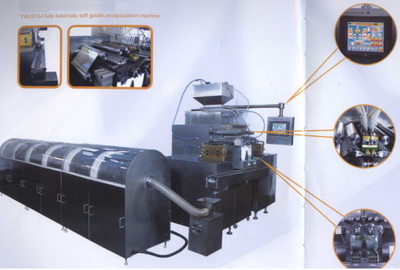

YWJ315 Soft Gelatin Production Line

Integrated the latest global encapsulation technology with our gelatin encapsulation experience, YWJ315 full automatic soft gelatin encapsulation machine is a new generation of soft gelatin encapsulation machine that has extremely large productivity (the largest in the world). The new soft gelatin encapsulation manufacturing facility features leading technology, simple but beautiful appearance, and it is another excellent product by our company for soft gelatin capsule clients around the globe.

Technical Parameters:

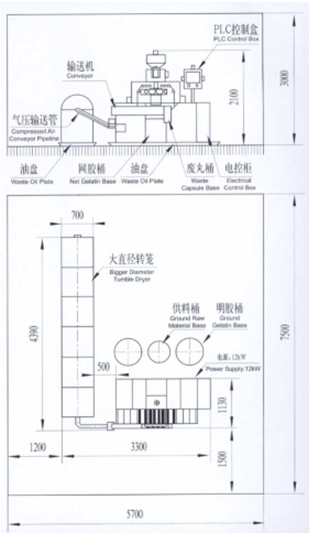

A. Die roller size: Φ157x315mm;

B. Mould cavity (8# OV): 560pills;

C. Die Roller revolution: 0-5rpm (adjustable variable speed);

D. Single plunger charge of feeding pump: 0~2ml(adjustable continuously);

E. Plunger charge number: 24;

F. Precision in loading: ±2%;

G. Output(8# OV): 134,4000pills/hrs(Die roller revolution 4rpm);

H. Gross power: 12kw;

Overall size(LxWxH): 1800x1060x1900mm.

Features of The Machine:

The size of mould is maximized by computer optimum design (Φ157x315mm).

Holes of the left and right main axis are processed with extreme accuracy on the boring machine imported from Switzerland. Though the die roll has been extended in length, it still ensures a high coaxial degree that guarantee the smooth seam and finished product rate of the soft gelatin capsule.

Pneumatic clamping system makes capsule filling process more simple and reliable.

Electronic hoisting sprinkler can stop at any position according to requirement and reduces the workload of workers.

Rotation speed of each gelatin skin wheel and main axis can be adjusted respectively by a single inverter so that the operator can make adjustment according actual requirement.

The minimal quantity lubrication feature enables adjusting the volume of lubrication at will until minimum level.

Optimum adjustment of open degree of the gelatin box makes it more convenient, fast and accurate to the adjust the gelatin membrane thickness.

Precise adjustment of open degree of the gelatin box makes it more convenient, fast and accurate to the adjust the gelatin membrane thickness.

Automatic controlled water cooling is used in the cooling of gelatin skin. The new method helps to save energy (save half to the normal energy consumed in cooling) and keep sanitation.

Cooling air design at the exit of gelatin box makes the gelatin capsule more beautiful.

Conveyor at the discharging area prevents soft gelatin capsules from pilling up at the exit.

Insulation design of the hopper makes it easier to fill suspension into the soft gelatin capsule.

Rectangle nozzle design of the sprinkler makes it easier to make more beautiful soft gelatin capsule.

PLC true color touch screen technology adopted by the electronic control system displays simulated operation of the machine. The concise and clear control interface ensures easy and fast control, and realize network monitoring, statistics and reports output.

Professional PID technology adopted by the PLC system enables precise adjustment of the sprinkler temperature and improves forming rates of the soft gelatin capsule.

The touch screen provides professional “recipe” function that can save production parameters and recall them by one key only.

Installation Drawing:

Soft Gelatin Capsule

Soft Gelatin Capsule Introduction:

Soft gelatin capsule has being more and more widely applied in various fields of drug, nutriceutical and cosmetic. The soft gelatin capsule is a sealed capsule usually filled with liquid and has a fortified and tough shell consists of gelatin and glycerol. Soft gelatin capsule is used to encapsulate liquid, suspension, paste or particle quantitatively in sealed capsules of various size and shape.

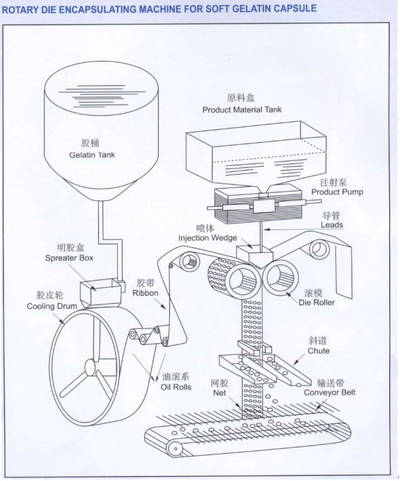

Different from the two-step manufacturing (shaping and filling) of hard gelatin capsule, the soft gelatin capsule is made on a rotating mould in a continuous one-step operation. Gelatin skin made of gelatin and glycerol passes through two die rolls facing each other and continuously rotating in reverse cycles and forms in shape in the mould cavity. The size and shape of the soft gelatin capsule are determined by the mould cavity. Material filling and sealing of gelatin skin is carried out in the same time so that the filling process ends right before the finish of sealing.

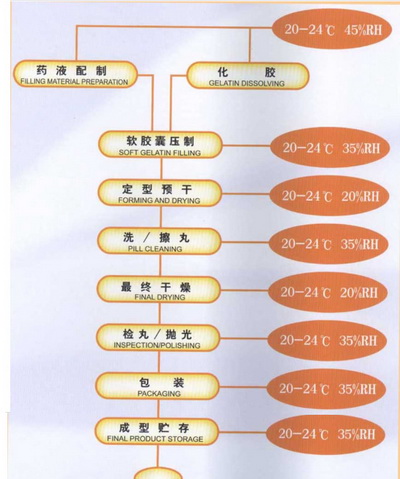

Filled capsule is put into tumble dryer for forming and drying, and then it is cleaned and dried finally. After visual inspection, the capsule is packed up and stored in the warehouse.

Merits of Soft Gelatin Capsule:

The soft gelatin capsule has tidy and beautiful appearance. Compared to tablet pills, it features faster disintegration speed, higher bioavailability and convenient ingestion, storage and taking along.

The capsule can cover unpleasant odor of the medicine.

The capsule can be made into instant-effective, slow-releasing, enteric coated or gastro coated soft gelatin capsule.

Both medicine with dosage form of higher oil concentration that cannot be easily made into tablets or pills and small dosage principle agent that is not water-soluble and hard to be ingested in the digestive.

Light-sensitive and usstable drugs can be filled into opaque lightproof opageopa capsule to improve the stability and prevent the drug from been affected by moisture, oxygen and light in the air.

Completely sealed package ensures the intactness of its content and provides counter fake function.

The soft gelatin capsule can be used to make neutriceuticals, cosmetics and paintball for simulated shooting.

Disadvantages:

Water solution of the drug or diluted alcohol can dissolve gelatin, therefore they cannot be packed in soft gelatin capsules.

The capsule disintegrates easily under high temperature and heat.

Workflow of Soft Gelatin Capsule:

Rotary Die Encapsulating Machine for Soft Gelatin Capsule:

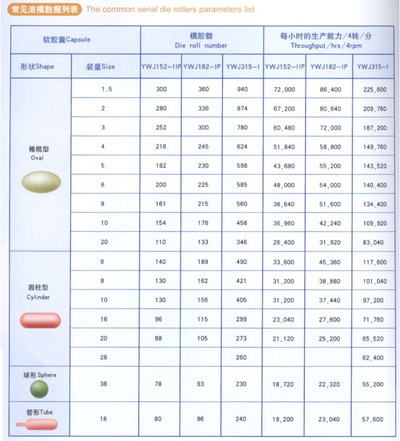

Die Rollers: