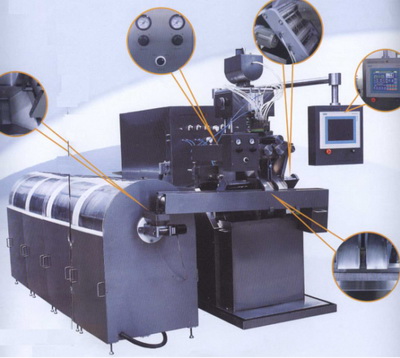

YWJ182 Soft Gelatin Production Line

YWJ182 die roll soft gelatin encapsulation machine

YWJ182-IP is a die roll soft gelatin encapsulation machine (specially for export) based on the advanced technologies both at home and abroad. With a mold length up to 182mm and new arrangement of mold hole, its output is 60% higher than the former type 152, thus, the requirements of customer need high production will be met. The integration of the technologies such as pneumatic clamping and minimal quantity lubrication make this machine unique in domestic market

Technical parameters:

Rotational speed of the die roller: 0-7rpm

Size of the mold roller: 103×182mm

Gelatin capsule output: 62100 pills/hrs(8#OV 5rpm)

Single plunger charge: 0-2ml

Charge variance: no more than±2%

Lubricant consumption of skin: ~300ml/h (5rpm)

Gross power: 13Kw

Overall dimension: 755×2200×1900mm

Advantages:

High productivity:

As the mold is extended to 182 mm, the productivity will increase extensively, e.g. the productivity will increased 60% for # 8 OV mold.

Skin lubrication:

The lubricant consumption is minimized as minimal quantity lubrication technology is adopted – the lubricant consumption is only 260 g/hrs when the rotational speed of the mold roller is 5rpm with the oil supply can be adjusted arbitrarily

C. Human machine interface:

Siemens Programmable Logic Controller (PLC) and Siemens true color touch screen used, and to ensure the stable control and superior properties of the electric control system, all the electric control parts are imports. Therefore, various indices of soft gelatin encapsulation machine are guaranteed.

1. SIEMENS PLC control adopted. Operated with SIEMENS TP270 touch screen. (pressure environment resistant, long life).

2. Fault diagnosis function.

3. Running of machine vividly and clearly simulated and displayed, all the parameters got at a glance.

4. Remote communicable, report uploaded to make information of production situation available at any time.

5. User-friendly, parameters centralized displayed, easy to be undertaken, and visualized operation.

6. Unique “recipe” function, one-key saving of the parameters, can be called at any time (optional).

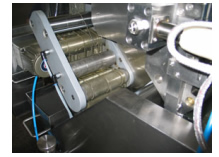

D. Pneumatic clamping, sprinklers pneumatically raised:

The molds are compressed pneumatically to avoid the mold damage because of mis-operation, thus lower the skin consumption during setting; pneumatic raising of sprinklers results in lower labor intensity of the workers and higher stability and reliability of movement.

E. Rectangle nozzle design of the sprinklers

On one hand, the rectangle nozzle design of the sprinklers efficiently lowered the spraying speed of the medical solution to get more aesthetic shape of gelatin capsule and therefore less product leakage; on the other hand, viscous medical solution can be pressed more easily.