FJZ Powder Calculating and Packing Machine

Introduction:

This is integrated equipment for antibiotic bottles racking & pressing which automatically complete vial feed, bottle racking, can automatically send to press, press and finish. It has a simple structure, reliable movements and stable performance which make it as the ideal equipment for the pharmaceutical factories' bottles producing.

Main Specifications:

Production capacity: 80~85 bottles/min.

Application Range: 7m - 20ml antibiotic bottle

Filling volume: 0.1 -1g

Filling Accuracy: ±2 %~ ±5 %

Power: 2KW

Electric Source: 220V 60Hz 3phase 4wire

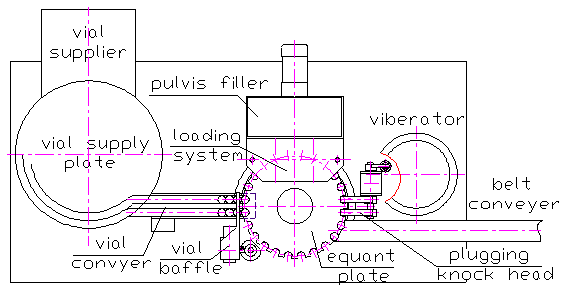

Operating Principle:

The empty vials are pushed into the vial supply plate by vial supply filler, with the rotation of the vial supply plate, the vials enter the track and the conveyer in turn, the conveyer will convey the vials to the gaps of the equal plate which is intermittent moving, each time the plate rotates, it passes 2 gaps, 2 vials will be taken away to the filling position, plugging and pressing position and finish position. When the bottle is sent to the filling and racking position, the photoelectric head will transfer the signal to the step motor, the step motor drives the metering screw and fill the bottles into the vials from the filler; when the filled vial is conveyed to the plugging position, the rubber plug is gripped by the plugging knock head, the plug is pressed on the vial neck; the plugged and pressed vial will be conveyed to the finish position and conveyed to the next procedure.

Filling: fill the material into the chamber, start the bottles convey motor, the motor drives the delivering screw within the chamber to deliver the bottles into the filler, when the height of the bottles in the chamber reaches the height of the observation window, the system can be started (when the height of the bottles in the chamber exceeds the center of the observation window, the motor shall be stopped). The rotation screw in the filler can homogenize the bottles automatically, the bottle is delivered to the measure screw, the photoelectric sensor detected vial, a signal will be sent to the CIP, CIP sends a pulse to the step motor, the motor operate once according to the preset rotate speed and distance; when the motor rotates, it drives the measure screw to rotate, bottles will be pushed into the vials by the screw.

Main Structure: