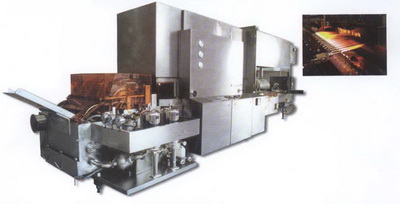

ALX-B Ampoule Liked Production Line

ALX-B series ampoule washing-drying-filling-sealing linked unit is designed and developed by our factory on the of importing, digesting and absorbing foreign advanced technology, and on the collection of design and manufacture experiences of 30 years on small volume liquid filling linked production line, it is a linked production line applicable for ampoule production. ALX-B ampoule washing-drying-filling-sealing linked unit is a complete production line composed of ACQ18/1-20ml(QCA12/1-20ml) series ampoule ultrasonic washing machine, ASMR600/43(SLAL400/32) sterilizing dryer, and AGF10/1-2ml (AGF8/1-20ml) (DGA6/1-20ml) ampoule filing-sealing machine. It is applicable for water and air spray washing alternately the B type easily broken retort ampoule, hot air laminar dry and sterilize, multiple needle filling and sealing.

The whole machine is under PLC control, it can be linked controlled, and it can be operated with single machine. The working state of each position can be automatically supervised, and it is displayed by light pole, or by man-machine interface. In the clean room, detector may be mounted for site supervision, and automation control level is high. This machine has PC automatic checking function, once the machine is failed, it can shut down the machine immediately and display the failure position and display troubles shooting for easy repair. On the washing control cabinet, there are lights feedback the working states of the filling machine and visual talking, or man-machine interface display and control. The operator can know the working state in the cleaning room at any time. The sterilization dryer uses surface cooler technology; it completely realizes no-suction wind and zero discharge. The filling machine has high position stop device, PLC controls the stop filling on lack of bottle, it is precise and reliable. The machine has different filling programs for customer to choose. The production can be counted. The machine will alarm on fuel gas leakage. The visual talking technology makes the communication between bottle washing area and clean filling area face to face, and makes the communication more directly.

ALX-B technical parameter

Model number |

ALX-B |

Type of unit |

QCA12/1-20ml

SZAL400/32A

DGA6/1-20ml |

ACQ18/1-20

ASM600/43

AGF8/1-20ml |

ACQ18/1-20ml

ASM600/43

AGF10/1-5ml |

Applicable specification |

1ml, 2ml, 5ml, 10ml, 20ml |

1ml, 2ml, 5ml, 10ml, 20ml |

1ml, 2ml, 5ml, |

Max production |

16000 denier/h

12000 denier/h

8000 denier/h

4500 denier/h |

22000-24000denier/h

16000 denier/h

1100 denier/h

6000 denier/h |

24000-26000denier/h

18000 denier/h |

Product qualified rate |

98% |

Filling pump precision |

≤±2% |

Distilled water |

0.25Mpa 50℃

≈0.5m3/h |

0.25Mpa 50℃

≈0.6m3/h |

0.25Mpa 50℃

≈0.6m3/h |

Compressed air |

0.25Mpa

≈50m3/h |

0.25Mpa

≈60m3/h |

0.25Mpa

≈60m3/h |

Nitrogen gas |

Max1.5 m3/h |

Max3.0 m3/h |

Max3.0m3/h |

Gas |

City gas 1.5 m3/h

Coned ensilages 0.3 m3/h |

City gas 2 m3/h

Coned ensilages 0.4 m3/h |

City gas 2.2 m3/h

Coned ensilages 0.45 m3/h |

Oxygen |

For city gas 0.9 m3/h

For LPG 1.3m3/h |

For city gas 1.2 m3/h

For LPG 1.7m3/h |

For city gas 1.4 m3/h

For LPG 2.0m3/h |

Suction air |

Filling Machine≥360m3/h

Sterilizing dryer≥1500m3/h

Wind Pressure≥500Pa |

Filling Machine≥360m3/h

Sterilizing Dryer≥3000m3/h

Wind Pressure≥500Pa |

Filling Machine≥360m3/h

Sterilizing Dryer≥3000m3/h

Wind Pressure≥500Pa |

Total power |

51.94KW |

62.74KW |

62.74KW |

Operator |

3 |

3 |

3 |

Outline dimension |

7540x2120x2380mm |

8191x2150x2450mm |

8191x2150x2450mm |

Weight |

5200Kg |

5710Kg |

5710Kg |

|