Assistant Equipment of Soft Capsule Lines

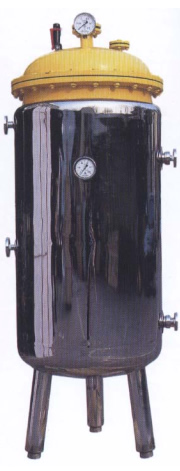

1.PLG-I Stainless Steel Agitator Compounding Tank:

Compounding Tank is the essential equipment in soft gelatin capsule packaging. The tank is made of high quality stainless steel and carbon steel. Two agitating blades are powered by X series cyclonical reducers featuring stable running, low noise and excellent working. Tank inner vessel and all its stainless steel parts have polished.

Technical Parameters:

o Working Temperature in the tank: 0~100oC;

o Working pressure in the tank: 0.02~0.09Mpa;

o Laboratory pressure in the jacket: 0.3~0.4Mpa;

o The seal piece can be used for more than 3,000 continuous hours

Size and Reducer Power:

Volume

(L) |

Total height(mm) |

Internal diameter(mm) |

External diameter(mm) |

Power

(kw) |

Revolution

(r/min) |

100 |

1700 |

Φ700 |

Φ900 |

1.5 |

35 |

200 |

1900 |

Φ700 |

Φ700 |

1.5 |

35 |

300 |

2100 |

Φ800 |

Φ900 |

2.2 |

35 |

500 |

2300 |

Φ1000 |

Φ1200 |

4 |

35 |

2.JTM80-I Standing Colloid Mill:

JTM80-I standing colloid mill features excellent breaking, emulsifying, homogenous and uniform mixing capability. For most solid materials, their grinding particles can reach diameters of three micrometers and machine can perform similar machinery tasks of the colloid mill an ideal processing facility for ultrafine particles .The agitator and plasma-grinding machine.

Construction Characteristics:

o Major spare parts are made of high quality stainless steel and free corrosion and poison.

o The major working parts, rotator and stator, are made by advanced technology and excellent processing. The adjusting ring, with the measuring scales on it, is easy to read, use and can make micro-adjustment between the spaces so sa to ensure the quality of products.

o According to different processing materials, rotators and stators made of various ingredients are available at our company. The are all easy to disassemble and clean.

Models and Technical Parameters:

Models Parameters |

JTM80-I |

Motor |

Models |

Y112M-2-B5(special) |

Power(kw) |

4 |

Revolution R.P.M |

2890 |

Size L×W×H(mm) |

450×465×1130 |

Weight (kg) |

190 |

3.HJG-11 Waterbath Gelatin Dissolving Unit:

Gelatin dissolving unit is the essential equipment in gelatin preparation.

Models

Name |

HIJ-11-03 |

HIJ-11-045 |

HIJ-11-06 |

HIJ-11-08 |

HIJ-11-10 |

volume |

L=300 |

L=450 |

L=600 |

L=800 |

L=1000 |

Reducer power(kw) |

3 |

4 |

5.5 |

7.5 |

7.5 |

Torque(kg/cm) |

2000 |

2500 |

2800 |

3000 |

3400 |

Agitator rotating speed(r/min) |

51 |

51 |

51 |

51 |

51 |

Internal diameter(mm) |

1000 |

1000 |

1200 |

1300 |

1400 |

External diameter(mm) |

1200 |

1200 |

1400 |

1500 |

1600 |

Total altitude(mm) |

2000 |

2200 |

2200 |

2400 |

2400 |

Supporting leg distance(mm) |

1450 |

1450 |

1650 |

1750 |

1850 |

Weight(kg) |

1100 |

1200 |

1400 |

1500 |

1700 |

A: Reducers are all X series cyclonical reducers.

B: Total altitude is the distance from discharge valve to the top of motor reducer.

C: The altitude from base of supporting leg to discharge valve is 600mm(300L); 750(450L-1000L).

D: The GDU is equipped with vacuum meter, pressure gage, thermometer and seal ring (food-class non-poisonous rubber ring).

E: Dg38 insulation ball valve made of special stainless steel is equipped at the discharge area.

Technical Parameters:

o The GDU is manufactured and examined in compliance with JB2880-81 Specification for Wielded Steel Normal Pressure Container

o Vacuum degree in the vessel: 0.02-0.09Mpa

o working pressure in the vessel: 0.03-0.05Mpa

o Laboratory pressure in the jacket:0.3-0.4Mpa

o working pressure in the jacket:0.03-0.098Mpa

o working temperature in the jacket:50-100℃

o Conveyor granule: more than 30CP

o The seal piece and seal ring can be used for more than3,000continuous hours

o Insulation layer uses super-fine glass cotton

o On inner vessel and insulation layer (covered with leather) of the tank, those sections exposed to liquid material are all made of 1Cr18Ni9Ti high quality stainless steel

o jacket of the GDU uses high quality carbon steel

o The GDU and all its stainless steel parts are well-polished

4. SZB Water Ring Vacuum Pump:

SZB cantilevered water ring vacuum pump can be use to suck in air or other gas that are non-water-soluble and do not contain solid particle With maximum Vacuun degree being 85%,the pump is especially suitable for gelatin preparation.So far the following models are available:SZB-4 and SZB-8.Respectively,”4”(“8”) refers to the gas flow rate (L/s) under 520mmHg.

Performance:

Model |

Exhausting volume |

mmHg |

Maximun vacuum degree? |

Revolution

(r/min) |

Power of the motor(kW) |

Caliber |

Pump Weight |

m3/h |

L/s |

Inhalation |

Exhalation |

SZB-4 |

19.8 |

5.5 |

440 |

80% |

1410 |

1.51.1.5 |

ZG1” |

ZG1” |

42 |

14.4 |

4 |

520 |

7.2 |

2 |

600 |

0 |

0 |

650 |

SZB-8 |

38.2 |

10.6 |

440 |

80% |

1430 |

2.2 |

ZG1” |

ZG1” |

45 |

28.8 |

8 |

520 |

14.4 |

4 |

600 |

0 |

0 |

650 |

5. SGR Series Hot-water Type Pipeline Mounted Pump:

SGR series hot-water-type pipeline mounted pump is applied to the pressured circulation of high temperature water, especially in melting gelatin. The temperature of operation id below 140℃

Model |

(m3/h)

Volume of flow |

(m)

Head |

(mm)

Caliber |

(%)

Efficiency |

(kW)

Motor power |

(V)

Voltage |

(mm)

Distance from inlet to outlet |

(k(kg) |

40SGR6-20 |

6 |

20 |

40 |

65 |

0.75 |

380 |

275 |

16 |

Conditions of Operation:

The water pressure of inlet pipe should not be above 3Kg/cm2 or below 0.2kg/cm2.

The water should be clean water without fiber or solid granule, and in regard to hot water, it should be soft water.

The temperature of media: the temperature of cold water should not be below 0℃.

The temperature of ambience should not be above+45℃.

Voltage of power supply is 380V .

6.RSQ-I Insulation Serpentine Water Heater:

The tank is one of the essential auxiliary equipments for water bath gelatin dissolving unit during the gelatin dissolving process. As a must have heating method during soft gelatin encapsulation process, water bath helps to keep the viscosity of the gelatin liquid:yet the viscosity of gelatin liquid could only be stable under constant heating at 90℃-100℃. The tank meets the above requirement by a series of special designs: serpentine heating design ensures recycled use of hot water; outer tank layer is covered by super-fine glass cotton insulation layer; and the outer skin is sealed with high quality stainless steel. The tank features convenient cleaning and good insulation function and is professional energy-saving heat exchange equipment.

Technical parameters:

o The GDU is manufactured and examined in compliance with JB2880-81 Specification for Wielded Steel Normal Pressure Container.

o Hot water volume:2000kg/h

o Working temperature :85-100℃.

o Overall dimension :Total altitude 2100mm×External diameter 700mm

o Weight:350kg.

7.LNG-I Stainless Steel Serpentine Vacuum Condensed Water Tank:

The tank is one of the essential auxiliary equipments for gelatin dissolving process, which is designed to avoid air bubble and water vapor in the entire process and provide certain protection to the vacuum pump.

By utilizing the serpentine and the vacuum condensation water tank ,the tank manages to suck in air bubble, cool and collect the water vapor during the gelatin dissolving process, Cooled water vapor tank is equipped with water level indicator which could help to control the water content in the gelatin liquid in each step of the gelatin dissolving process.

Made of 1Cr18Ni9Ti high quality stainless steel, the tank has a well-polished surface which features convenient cleaning ,fast cooling, overall sealing,stable vacuum negative pressure and good control of the cooled water.The tank complies with the GMP sanitary and is an ideal auxiliary equipment for soft gelatin encapsulation.

Technical Parameters:

Overall dimension: 1A (60L) Total length 1750mmxExternal diameter 400mm

2A (80L) Total length 2000mmxExternal diameter 450mm

Weight: 1A 150kg; 2A 180kg

Vacuum degree: 0.09Mpa

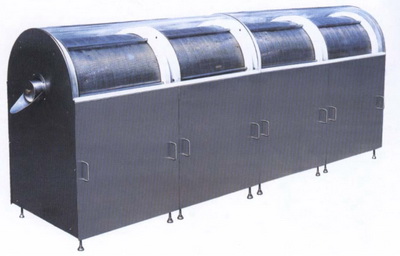

8.YGJ-II Fluidized Bed Tumble Dryer:

Fluidized bed tumble dryer can be used for shaping and after drying of soft gelatin capsule. It consists of four sections of tumbles, four fans and electric control system, Each of the four sections can rotate in both directions. The dryer can be either controlled automatically by PLC system when connected to the master station during shaping process, or controlled manually during pre-drying process. Water content in the gelatin skin can be reduced from around 45% to around 35% during the shaping process and it can be further decreased to around 25% in the pre-drying process. Drying method: fluid bed drying ,i.e. the drying system can blow the pill bodies to be fluidized, which minimizes the friction either between the pills or between the pills and the inner wall of the tumble. Increase drying speed greatly.

Technical Parameters:

Tumble rotating rate (r/min): 11

Tumble size (mm): 523×620

Power supply: 380V/50Hz

Power of the motor: 0.37kW×4

Fan air flow: 2200 m3/h×4

Power of the fan: 0.25kW×4

Fan rotating rate: 1250r/min

Overall dimension(mm) : 2800×700×1123

Gross power: 2.48kW

Weight: 800Kg

9.WFJ-1 Stainless Steel Soft Gelatin Capsule Net Gelatin Disintegrator:

The machine is the essential auxiliary equipment for soft gelatin capsule net gelatin disintegration, recovery and utilization process.

The machine body, feeding plate and external cover are all made of high quality stainless steel and well-polished series cyclonical reducers are used to drive this machine. The machine is fully sealed and features stable operation with low noise and reliable performance, easy breaking down and assembling, an well as resistance against corrosion, acid and alkaline. It fully complies with national GMP manufacturing standards and is ideal auxiliary equipment for soft gelatin capsule gelatin recovery.

Technical Parameters:

Reducer power:3kW(revolution:130/min)

Produce capability: 500-600kg/h, particles of soft gelatin capsule can reach more than 25-30.

Overall dimension: Length 1220mm×Width 550mm×Altitude 650mm

Accessories: 10 rotating knives; 5 static knives

Supplementary knives are available both by retailing or mail order upon consumer’s request.

10.LXJ-1 Three-pod-centrifuge:

The LXJ three-pod centrifuge is a top dumping batch operation centrifuge. It is suitable for isolation of solid granules≥0.01 mm from suspension. such as isolation of materials of granular, crystal or fiber shape. It can also be used for dehydration of textiles after washing. The machine has a simple but sound design which enables convenient machine can be widely used in food, chemical, textile and pharmaceutical industries.

Technical Parameters:

Model |

Rotor |

LXJ-1 |

Dia.

mm |

Operating altitude

(mm) |

Caliber of liquid block board (mm) |

Wall

thickness

(mm) |

Revolution

(rpm) |

Volume

(L) |

300 |

300 |

150 |

220 |

2 |

1390 |

18 |

600 |

600 |

280 |

400 |

3 |

1450 |

45 |

800 |

800 |

400 |

540 |

4 |

1200 |

98 |

1000 |

1000 |

400 |

700 |

6 |

1000 |

140 |

Model |

Motor |

Fractionation factor |

weight |

Overall Size |

LXJ-1 |

Model |

Power

(kW) |

D2/2g |

kg |

L×W×H

(mm) |

300 |

Y90S-4 |

0.75 |

556 |

100 |

620×620×650 |

600 |

Y100L-4 |

3 |

485 |

590 |

1200×1200×810 |

800 |

Y132S-4 |

5.5 |

643 |

1300 |

1550×1550×960 |

1000 |

Y132M-4 |

7.5 |

560 |

1500 |

1700×1700×980 |

11. XWJ-11 Ultrasonic Soft Gelatin Capsule Cleaning Machine:

Lubricating paraffin oil attached to the surface of the gelatin skin during pressure must be washed thoroughly. One-round cleaning of the gelatin capsules can be operated on the machine without squeezing between the capsules. The cleaning process is divided into: ultrasonic soak cleaning, immersion, separation of pill bodies and alcohol, and spraying: Cleaning method: ultrasonic cleaning; Cleaning cycle (from feeding to discharging):about 45sec.

Technical Parameters:

Cleaning capacity: (8# soft gelatin capsule, 500mg/pill)50,000pills/h

Operation: continuously running

Gross power: 2.2kW

Power supply: three-phase five-wire system? 380V/50Hz

Overall dimension: ( L×W×H, mm) 1200×920×1300

Weight: 200kg

12.LWJ-1 Caterpillar Fully Automatic Dryer:

Caterpillar fully automatic dryer is an important equipment for the final drying of the soft gelatin capsules. It has its own desiccation system (Japanese ceramic roller is used, which is cleanable, nonflammable, and with a life over 10 years) and refrigeration system, which alleviates the requirement for the room temperature and humidity. The whole drying process is fully automatic with manually agitation unnecessary. During the drying process, there are not overlapping and squeezing of the pills. The requirements of uniformity, low temperature and low humidity are met. The disintegration time of the capsule is shortened; the pills have no damage and adhesion. The machine can reduce the water content to below 14%, as is stipulated by the national pharmacopoeia; meanwhile it thoroughly eliminates disadvantages of the traditional tray and tumble, such as long drying time, unevenness(of capsule), high requirement for worker and environment, bad brilliance on the surface of the capsule.

Technical Parameters:

Capacity: 50,000pills/h

Drying cycle: 6-10h

Equipment operation: infinitely stage transmission

Desiccation capacity: 6kg/h

Power supply: three-phase five-wire system,380V/50Hz

Gross power: 9kW

Overall dimension: LxWxH, mm: 2400x1770x2150mm

Weight: 2000kg

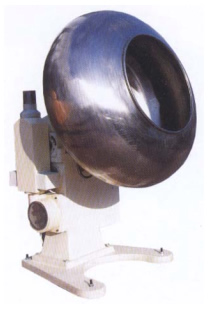

13. BY series soft gelatin capsule polisher:

Technical Parameters:

Parameters |

Models |

BY1000 |

BY800 |

Diameter of container body |

1000 |

800 |

Throughput (kg a time) |

50-70 |

30-50 |

Angle of dip (adjustable) |

15-45度 |

15-45度 |

Rotating speed of container body(r/min) |

28 |

32 |

Main motor |

Y90S-4

1.1kW

1400r/min |

Overall dimension:( L×W×H, mm) |

1100×1100×1600 |

925×900×1500 |

Weight(kg) |

250 |

230 |

BY series soft gelatin capsule polisher is used for after shape polishing .After being polished, surface of soft capsule becomes smooth and brilliant, look nicer, easy to recognize and alleviates dissolving of soft capsule in gastrointestinal tract.

14. Pneumatic Ground Gelatin Tank:

Gelatin tank is used to keep temperature of gelatin liquid needed for soft capsule preparation. Pneumatic ground gelatin feeding saved the investment for hanger in the workshops. PLC automatic control takes charge of gelatin feeding.

Gas consumption volume:50L/h

Utility volume of the gelatin tank:105L.

15. Pneumatic Ground Feeding Tank:

The pneumatic ground feeding tank feeds materials into the hopper by creating air pressure. Feeding of the material is finished in a circular system. PLC automatic control takes charge of the materials feeding.

Capacity of the tank: 90L

Air source:0.1Mpa, 50L/h